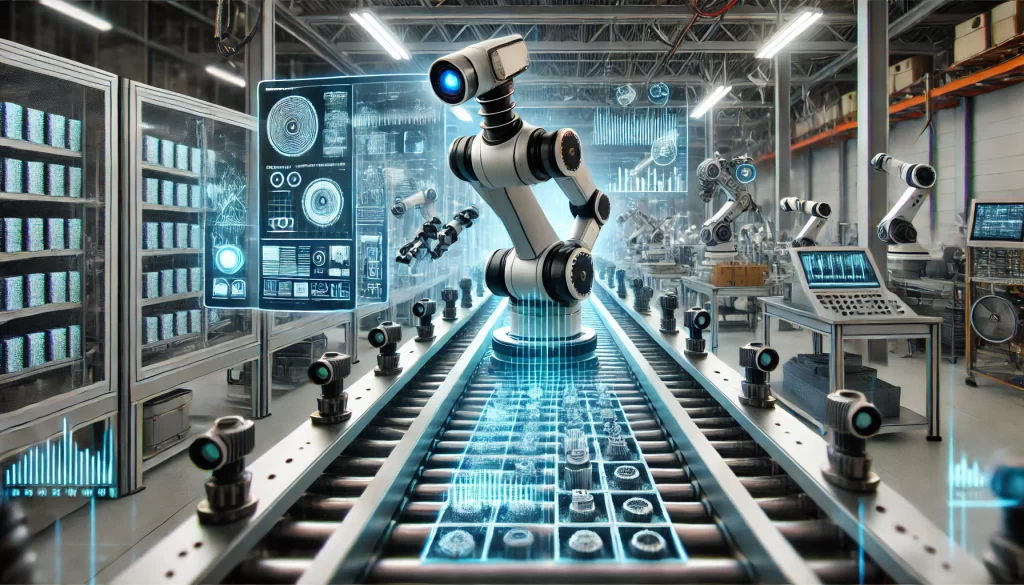

Robotic vision systems are crucial in manufacturing quality control. By utilizing cameras to zoom in on images of a product before it leaves the assembly line, robots that can “see” often identify imperfections that might be missed in manual, human inspections. Recent innovations have only allowed these vision systems to become more powerful and thus bolster quality control over countless industries.

Three particularly notable advances in robotic vision systems include:

- the incorporation of 5G technology,

- the fusion of vision systems and AI,

- and the use of hyperspectral imaging.

1. Machine vision is evolving with the incorporation of 5G technology.

5G is, as its name suggests, the fifth generation of wireless communication technology, and it offers incredible benefits for the manufacturing industry. For example: when paired with 5G, machine vision systems can transmit large amounts of data instantly, enabling faster decision-making and response times. The speed that 5G provides is essential to ensure operational efficiency in industrial automation.

This marriage of technologies isn’t just theory, either. A partnership between Ericsson and ABB produced in a 5G machine vision system tailored to automotive manufacturing. It boasts real-time transmission of high-resolution images and videos, which results in overall product quality improvements—like more precise defect detection.

2. AI and deep learning have proven invaluable for automated inspection processes.

Integrating AI and deep learning into robotic vision systems has proven nothing but beneficial for the manufacturing industry. In essence, this emerging tech provides vision systems with more human-like, intuitive recognition of images and their features. The machine in question can then process that information without external input and recommend or take actions depending on what it “sees.”

Again, the explanation above is more than an idea—it’s practical! Using artificial intelligence, newer robotic cells can rapidly detect objects in varied bins and then generate the optimal path for robots to take. These cells achieve decision-making speeds of less than half a second, comparable to the human brain. No longer will vision systems create a productivity bottleneck in quality control.

3. Hyperspectral imaging is becoming more popular.

A vision system that uses hyperspectral imaging—which captures visuals across numerous wavelengths of light—can offer a comprehensive analysis of products during manufacturing. Various industries have increasingly utilized this technique in automation for its superior accuracy in detecting product defects and irregularities.

Headwall Photonics, for instance, has engineered a hyperspectral imaging system for food processing companies in particular. Said system is so sophisticated that it can efficiently identify impurities and contaminants in a food item before it ever hits shelves—all by taking a look at its spectral image. It’s easy to see, therefore, where hyperspectral imaging could benefit quality control among a wide variety of manufacturers.

In conclusion, the latest advances in robotic vision systems are revolutionizing quality control.

To summarize:

- With the incorporation of 5G technology, these systems can now transmit data instantly, enhancing decision-making and response times critical for industrial automation.

- Furthermore, a combination of AI and deep learning has endowed vision systems with incredible recognition capabilities, optimizing defect detection.

- Finally, hyperspectral imaging has emerged as a powerful tool, offering unparalleled accuracy in identifying product defects.

These innovations underscore a transformative shift towards more precise manufacturing processes and promise enhanced product quality in many sectors. Request a consultation so we can discuss your needs!