In today’s fast-changing manufacturing landscape, staying ahead is crucial for maintaining a competitive edge. At 20/20 Robotics, we’re at the forefront of integrating cutting-edge technologies to revolutionize industrial automation. Let’s explore the core technologies that power our innovative robotics systems and how they’re reshaping manufacturing’s future.

Machine Vision: The Eyes of Automation

Machine vision is the cornerstone of our advanced automation solutions. By using high-end cameras and sophisticated software algorithms, our systems can perform real-time quality control inspections, detect defects with high accuracy and guide robots for precise object manipulation.

Our engineering team has extensive experience with all Cognex and Keyence platforms, ensuring we deliver the most effective machine vision solutions tailored to your needs. This expertise allows us to tackle complex visual inspection tasks across various industries, from automotive parts to pharmaceutical products. This technology can significantly reduce your quality control costs while improving accuracy, potentially saving your facility millions in rejected parts and customer returns.

OASIS: AI-Powered Optical Inspection

The Optical AI Surface Inspection System (OASIS) represents a significant advancement in machine vision technology. This system allows you to train cameras much like you’d train a human operator, distinguishing between good and bad products with remarkable accuracy.

OASIS’s user-friendly interface simplifies complex inspection tasks, even for those new to AI-powered systems. Its adaptive learning capabilities mean it can continuously improve its performance, reducing false positives and enhancing overall inspection reliability.

Robotic Programming: The Brains of the Operation

Our expertise in robotic programming enables us to create intelligent, adaptable systems that can handle a wide array of tasks with precision and consistency. We specialize in programming for industry-leading platforms, including Yaskawa and Fanuc.

These robotic systems form the backbone of our automation solutions, offering unmatched flexibility and efficiency across various manufacturing processes. From pick-and-place operations to complex assembly tasks, our programming ensures smooth, efficient and safe robotic operations. By automating repetitive tasks, you can redeploy your skilled workforce to more value-added activities, improving both productivity and employee satisfaction.

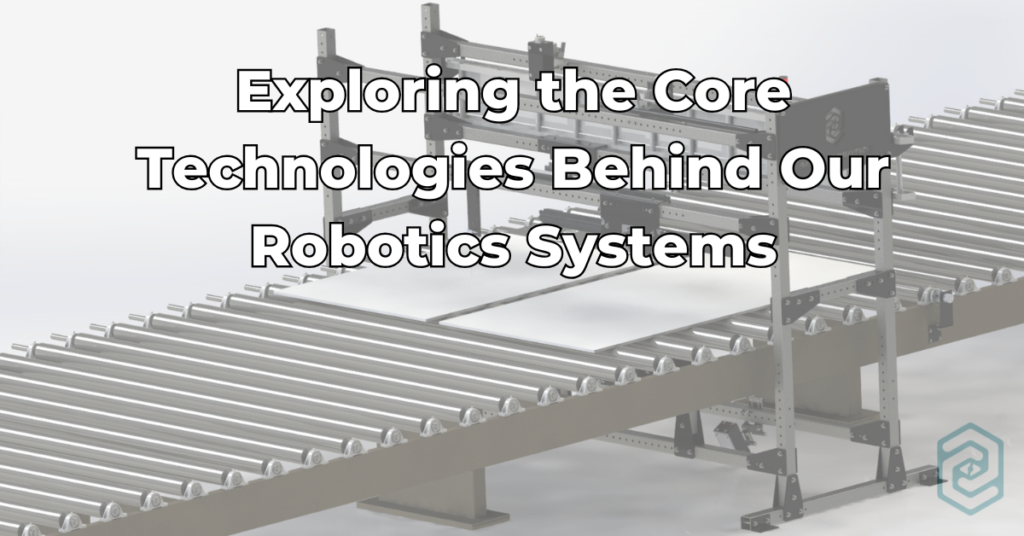

Mechanical Design: The Skeleton of Automation

At 20/20 Robotics, we understand that the foundation of any successful automation system lies in its mechanical design. Our team of experienced engineers creates custom solutions that fit your facility’s unique challenges and requirements, ensuring optimal performance and reliability.

We focus on creating robust, efficient designs that maximize productivity while minimizing downtime. Our mechanical solutions are built to withstand the rigors of your industrial environment, providing long-term value and reliability for your facility.

Integrating Technologies for Comprehensive Solutions

In today’s complex manufacturing environment, standalone technologies often fall short of addressing multifaceted challenges. At 20/20 Robotics, we understand the power of synergy. Our approach goes beyond individual components, focusing on creating seamlessly integrated systems that work in harmony to revolutionize your production processes.

What sets 20/20 Robotics apart is our ability to seamlessly integrate these core technologies into cohesive, intelligent automation systems. This integration allows us to offer solutions that address complex manufacturing challenges across various industries, including building materials, food and beverage, electronics, medical devices, plastics and packaging.

Our holistic approach ensures that each system component works in harmony with the others, maximizing efficiency and productivity. By leveraging the strengths of machine vision, robotic programming and precision mechanical design, we create automation solutions that are greater than the sum of their parts.

Guardian: A Prime Example of Integrated Technology

Our Guardian system exemplifies the power of integrated technologies. Combining high-end machine vision with advanced lighting techniques, Guardian ensures that products remain within the boundaries of pallets or service boards. This real-time monitoring and communication with line PLCs prevent potential crashes and improve overall efficiency.

Guardian demonstrates the practical application of integrated technologies in solving complex industrial challenges, providing real-time feedback and enhancing safety and productivity in material handling operations.

Ready to elevate your manufacturing processes with state-of-the-art robotics and machine vision technologies? Contact 20/20 Robotics today to explore how our cutting-edge solutions can transform your operations and get a demo of its applications.

Frequently Asked Questions

How does AI enhance machine vision capabilities?

AI takes machine vision to new heights by enabling systems like our OASIS to adapt to new inspection criteria with remarkable flexibility. This advanced technology allows for more nuanced quality control, significantly reducing false positives. Moreover, AI-powered vision systems excel at handling variations in lighting, product orientation, and other factors that often challenge traditional setups, resulting in more robust and reliable inspection processes.

What industries can benefit most from 20/20 Robotics’ solutions?

While our solutions are versatile, industries that often see the most significant benefits include food and beverage, electronics manufacturing, medical device production and building materials. These sectors typically require high precision, consistency and adherence to strict quality standards – areas where our robotics systems excel. However, any industry looking to improve efficiency, quality and productivity through automation can potentially benefit from our technologies.

How does 20/20 Robotics ensure its solutions integrate smoothly with existing systems?

Our team’s extensive experience across various platforms and industries allows us to design solutions that seamlessly integrate with existing equipment and workflows. We prioritize compatibility and scalability in our designs, ensuring that our systems enhance rather than disrupt your current operations. Before implementation, we assess your existing infrastructure to identify potential integration challenges and develop strategies to address them.

What sets 20/20 Robotics apart from other automation providers?

Our unique strength lies in our holistic approach to automation. By combining expertise in machine vision, robotic programming and mechanical design, we create comprehensive solutions that address complex manufacturing challenges more effectively than standalone technologies can. Our commitment to ongoing support and continuous improvement ensures that our clients receive long-term value from their automation investments.