Robotic Programming

At 20/20 Robotics, we specialize in providing cutting-edge robotic programming solutions tailored to meet our clients’ unique needs.

Unlocking the Power of Automation with 20/20 Robotics

In the rapidly evolving world of technology, robotic programming has emerged as a critical skill for businesses looking to streamline operations, increase efficiency, and stay ahead of the competition. At 20/20 Robotics, we specialize in providing cutting-edge robotic programming solutions tailored to meet our clients’ unique needs.

System Function & Capabilities

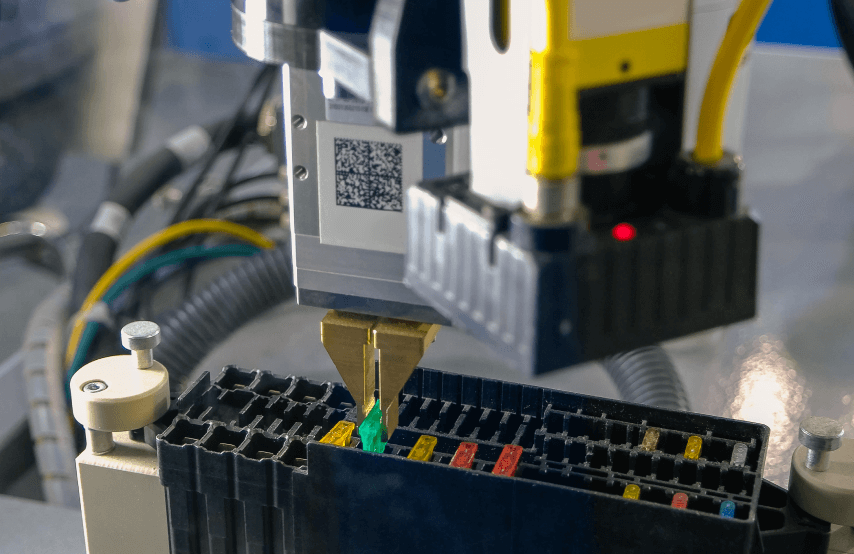

20/20 Robotics machine vision engineering team has extensive experience in machine vision programming across all Cognex and Keyence platforms.

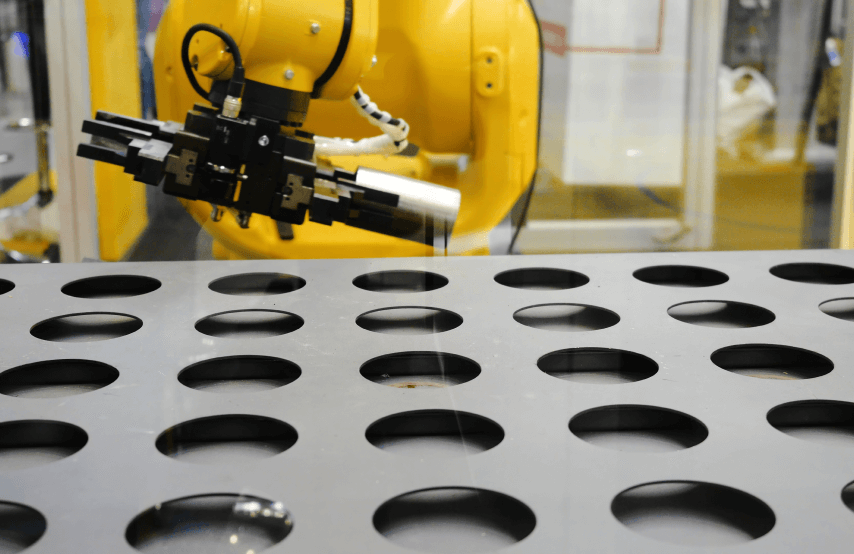

- High-Speed Pick and Pack

- Vision Guidance

- Palletizing

- Assembly

Our Robotic Programming Services

At 20/20 Robotics, our team of experienced programmers and robotics experts offer a comprehensive range of robotic programming services, including:

Custom Robot Programming

We develop tailor-made robotic programs that address your specific business needs, ensuring seamless integration with your existing systems and processes. Our team works closely with you to understand your unique requirements and develop a customized solution that maximizes the benefits of robotic automation for your organization.

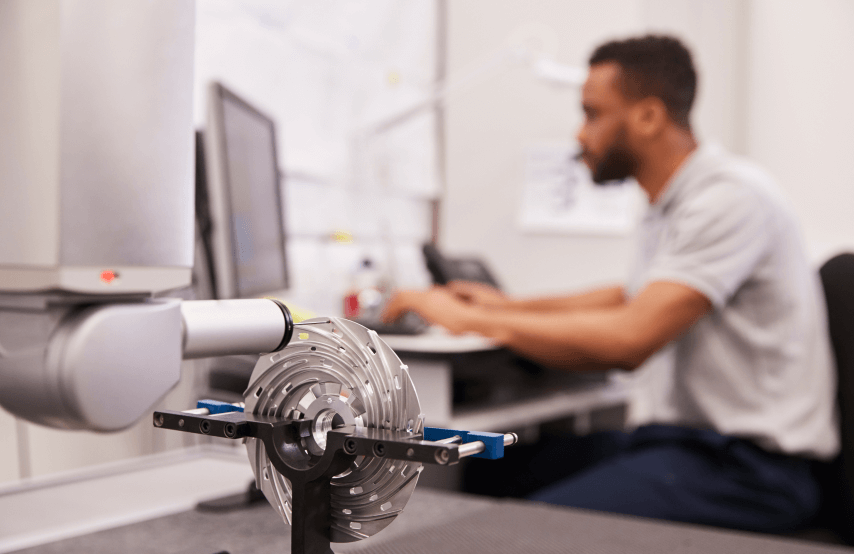

Robot Simulation and Testing

Our advanced simulation tools allow us to test and refine robotic programs in a virtual environment, minimizing downtime and ensuring optimal performance before deployment. By simulating the robot’s movements and interactions with its environment, we can identify and correct any potential issues before the robot is put into production, saving time and reducing costs.

Robot Integration and Deployment

We work closely with your team to integrate robotic systems into your workflow, providing ongoing support and training to ensure a smooth transition and maximum ROI. Our experts will guide you through the entire process, from initial planning and design to final installation and commissioning, ensuring that your robotic system is up and running quickly and efficiently.

Maintenance and Upgrades

Our team provides regular maintenance and upgrades to keep your robotic systems running at peak performance, adapting to evolving business needs and technological advancements. We offer comprehensive support and service plans to ensure that your robotic system remains reliable, accurate, and efficient over the long term.

Real Applications

Automotive Assembly

Our robotic solutions streamline automotive assembly processes, improving efficiency and precision while reducing the risk of human error.

Packaging and Palletizing

Robotic systems can handle complex packaging and palletizing tasks, increasing throughput and minimizing labor costs.

Material Handling

Enhance manufacturing with our advanced material handling automation, boosting productivity and efficiency seamlessly.

Machine Tending

Robotic machine tending systems optimize CNC machine operations, minimizing downtime and increasing overall equipment effectiveness (OEE).

Our Product Quality

From our robotic integration experts, you’ll learn the art of unlocking automation’s full potential, transforming your operations, and staying at the forefront of technological advancement.e to ensure that our solutions incorporate the latest and most reliable machine vision technologies. Our robotic integration experts are dedicated to delivering products of unparalleled quality, setting new standards in precision and reliability for your automation needs.

FAQs

We have extensive experience working with a wide range of robots, including those from leading manufacturers such as Yaskawa (Motoman) and Fanuc. Our team can recommend the best robotic solution for your specific application.

Robotics can enhance your manufacturing processes by increasing efficiency, accuracy, and consistency while reducing labor costs and minimizing the risk of human error. Robotic systems can also improve safety by handling dangerous or repetitive tasks.

Yes, our team specializes in the integration of robotics and machine vision systems. By combining these technologies, we can create powerful automated solutions that enhance quality control, inspection, and guidance capabilities.

At 20/20 Robotics, we offer comprehensive support for our robotic solutions, from initial consultation and system design to installation, programming, and ongoing maintenance. Our team is dedicated to ensuring the long-term success and reliability of your robotic systems.

Robotic programming can be applied across a wide range of industries, including manufacturing, logistics, health care, agriculture, and more. Our solutions are designed to be flexible and adaptable, allowing businesses in any industry to leverage the power of robotic automation to improve efficiency, reduce costs, and enhance quality.

The timeline for implementation varies depending on the complexity of the project and your business’s specific requirements. Our team will work with you to develop a customized plan and timeline that considers your unique needs and constraints, ensuring that your robotic system is up and running as quickly and efficiently as possible.

Common programming languages used in robotic programming include C++, Python, Java, and MATLAB, among others. Our team has expertise in a variety of languages and can select the best option for your specific application, ensuring that your robotic system is optimized for performance, reliability, and ease of use.

Yes, our robotic programming solutions are designed to integrate seamlessly with your existing systems and processes, ensuring a smooth transition and minimal disruption to your operations. We work closely with your team to understand your current infrastructure and develop a customized integration plan that maximizes the benefits of robotic automation for your organization.

Contact Us

- 708.887.8650

- info@2020robotics.com

- 121 Shue Dr., Anna, OH 45302