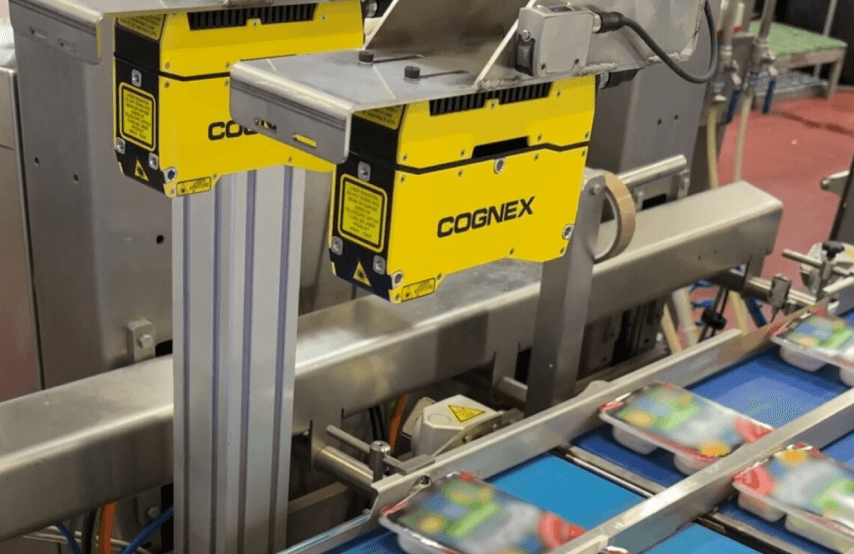

Machine Vision Programming (Cognex/Keyence)

20/20 Robotics machine vision engineering team has extensive experience across all Cognex and Keyence platforms.

Machine Vision Specialists

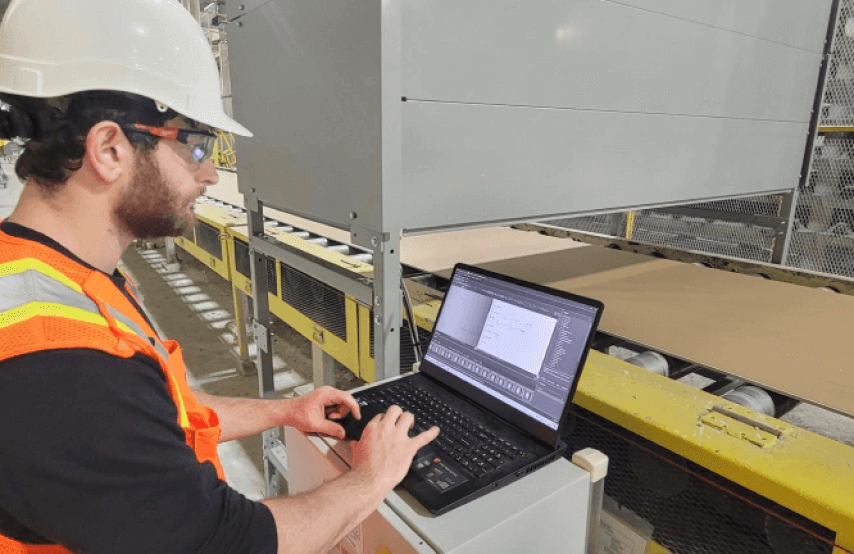

Machine vision programming is a specialized field focused on developing software algorithms to extract meaningful information from images captured by cameras. By utilizing advanced imaging techniques, precise lighting, and tailored lensing, machine vision systems can significantly improve the accuracy and productivity of various applications. These systems are essential in automating quality control processes, enabling real-time inspection and defect detection, and optimizing manufacturing workflows. The result is enhanced efficiency, reduced operational costs, and superior product quality across diverse industries, from automotive to pharmaceuticals to food and beverage and beyond.

Cognex and Keyence

20/20 Robotics leverages cutting-edge machine vision hardware and software from industry leaders Cognex and Keyence to deliver custom solutions across multiple industries. By integrating these advanced technologies, systems can be produced with unparalleled levels of accuracy, reliability, and productivity in daily operations. 20/20 Robotics’ expertise in machine vision programming, combined with the robust capabilities of Cognex and Keyence products, allows for tailored solutions, ensuring precise quality control, efficient process automation, and superior operational performance. Whether in manufacturing, automotive, electronics, or other sectors, our custom machine vision solutions help optimize workflows, reduce errors, and enhance overall productivity.

Example Applications

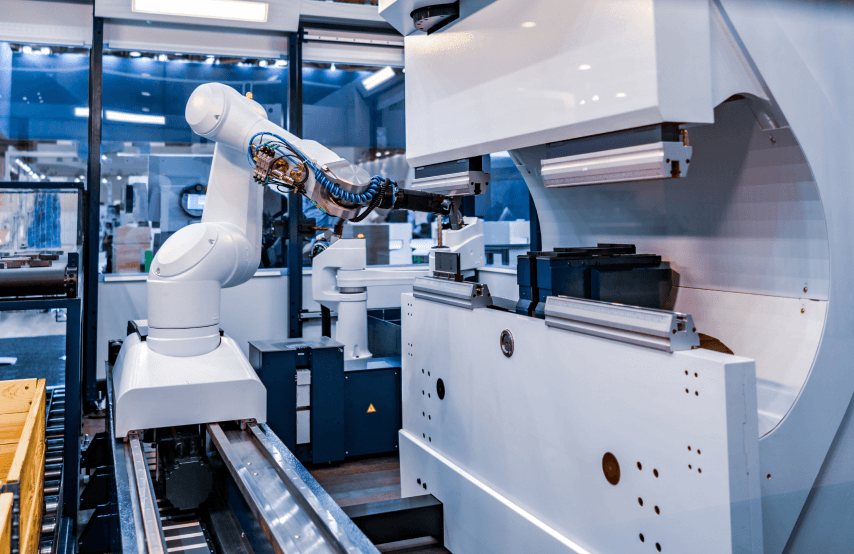

Automotive Part Inspection

Machine vision systems can inspect automotive parts for defects, verifying critical dimensions and ensuring consistent quality throughout the production process.

PCB Assembly Verification

By inspecting printed circuit boards (PCBs) for proper component placement, solder joint quality, and other factors, machine vision helps ensure the reliability and functionality of electronic assemblies.

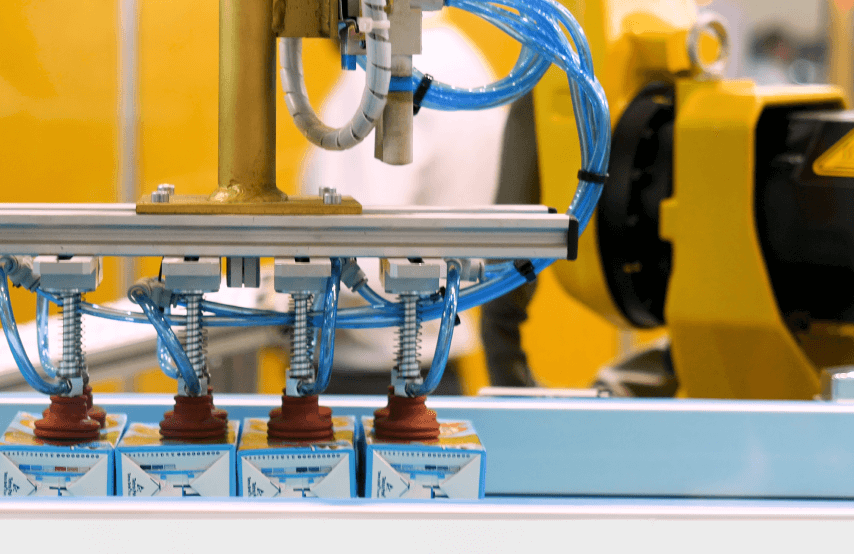

Packaging Quality Control

Machine vision can verify packaging integrity, label accuracy, and product presence, helping manufacturers maintain high standards for their packaged goods.

Food and Beverage Inspection

In the food and beverage industry, machine vision systems can detect contaminants, verify fill levels, and ensure proper packaging and labeling, contributing to food safety and quality.

Our Product Quality

At 20/20 Robotics, we pride ourselves on delivering machine vision solutions of the highest quality. Our experienced team of engineers works closely with you to understand your specific requirements and develop customized systems that meet your exact needs. We partner with industry-leading providers like Cognex and Keyence to ensure that our solutions incorporate the latest and most reliable machine vision technologies.

FAQs

Machine vision is valuable across a wide range of industries, including automotive, electronics, packaging, food and beverage, pharmaceutical, and more.

Machine vision systems can achieve much higher levels of accuracy and consistency than human inspectors, as they are not subject to fatigue, distraction, or subjectivity.

Yes, modern machine vision systems are designed to operate at high speeds, enabling them to keep pace with even the fastest production lines without compromising accuracy.

The best way to determine if machine vision is right for your application is to consult with an experienced provider like 20/20 Robotics. Our team can assess your needs and recommend the most effective solution.

Contact Us

- 708.887.8650

- info@2020robotics.com

- 121 Shue Dr., Anna, OH 45302