Dunnage TopBot

Revolutionizing Automation in Corrugated Manufacturing

Dunnage TopBot

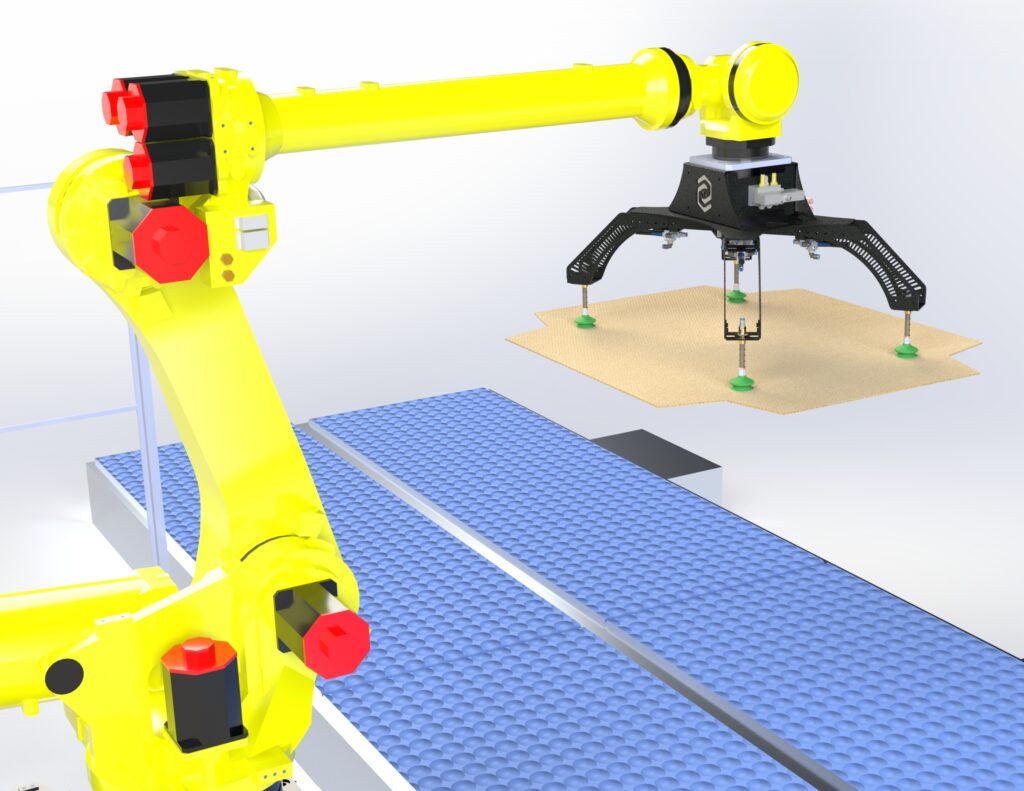

Experience the future of efficiency with the innovative TopBot, designed to automate the precise placement of dunnage onto corrugated sheet stacks and bundled units. Advanced robotics and machine vision provide automation solution to the last manual operation on the corrugator.

Product Capabilities

The Dunnage TopBot system is designed to handle over 200 units per hour, achieving an impressive throughput rate that ensures efficiency in high-demand environments. Its pick rate is optimized to handle a single dunnage sheet every 15 seconds or two sheets within 30 seconds. This is made possible through a custom-engineered end-of-arm tool, equipped with advanced vacuum grippers for precision handling.

At its core, is the powerful Fanuc R2000iC robot, capable of operating within a reach of 122 inches. For precise sheet placement, the system integrates a Cognex vision system that guides the robot with high accuracy. Safety is a priority, with integrated safety scanners ensuring secure operations. Control and monitoring are managed through an Allen-Bradley PLC and HMI, offering seamless control of the entire process.

- 200+ Units Per Hour Throughput

- Rapid Pick Rates

- Custom End of Arm Tool with Vacuum Grippers

- Long 122” Reach

- Cognex Vision System for Sheet Placement

- Integrated Safety Scanners

- Allen-Bradley PLC and HMI

Boost Your Productivity

Advanced Machine Vision

TopBot utilizes 3D vision systems to adapt to varying stack sizes and configurations, providing reliable performance every time.

Increased Productivity

With cycle time as little as 15 seconds, the TopBot can keep pace with high-speed strapping equipment…processing units in excess of 200 per hour.

Improved Product Quality

The robotic precision of TopBot creates units with dunnage placement accuracy; yielding improved appearance and consistency as it ships to your Customer.

Operator Savings & Safety

TopBot reduces dependance on manual labor for dunnage application; reducing direct cost and potential for injury of operators working in a moving conveyor zone.

Our Product Quality

20/20 Robotics has extensive experience in Robotic and Machine Vision Applications. From project consulting to full system integration, we have you covered! Let us help create a vision of your automated future.

FAQs

The Dunnage TopBot can be located prior to the strapping machine. The dunnage placed on top of the unit is the last point in the production process where an operator physical touches the product.

By improving throughput of the system to maximize your strapper machine. Additionally it gives your operator more time to focus on the other tasks that occur in the area.

Through the use of 3D machine vision, the Dunnage TopBot has the capability to make placement adjustments on the fly. The 3D images gives the robotic system the ability to find the corrugated unit regardless of size and location.

Contact Us

- 708.887.8650

- info@2020robotics.com

- 121 Shue Dr., Anna, OH 45302